|

Mill/Turn

The most widely-used CAD/CAM software in the world now

gives you the confidence to automate your complex

programs on today’s high-powered, multi-streamed,

multitasking machining centers. Program it right the

first time, every time.

“The Mastercam Mill-Turn

product unlocks the full potential of my customer’s

machines, and with the ease of the drag and drop sync

manager and fully modeled

machine simulation, it

gives me the confidence to use it.”

Jeremy

Herron, DBS Solutions, LLC, Taylors, SC

RUN

WITH PRIDE. RUN WITH CONFIDENCE.

Mastercam

Mill-Turn simplifies your most complicated projects.

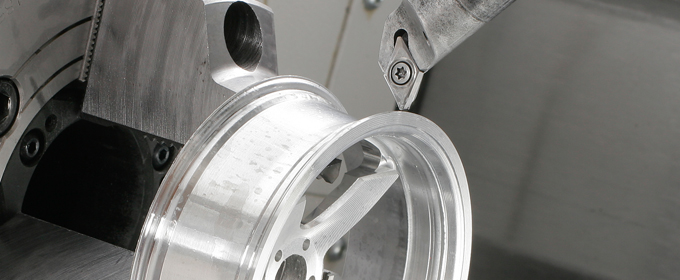

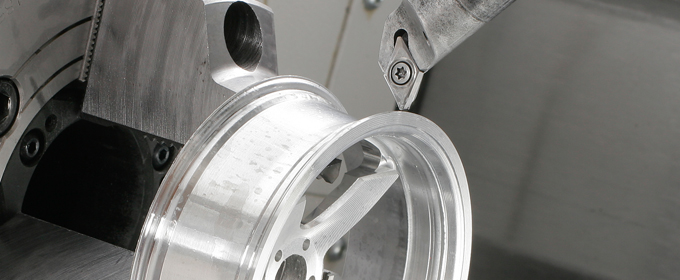

Mastercam Mill-Turn simplifies today’s high-powered,

multi-stream machining centers. Designed to compliment

Mastercam’s powerful milling and turning toolpaths,

Mill-Turn delivers the best in shop-tested cutting

techniques combined with the latest in machine and

toolpath management and verification.

Your

workflow is easy: Choose your machine and Mastercam

Mill-Turn automates part transfers, toolplanes, stock

definition, and setup. Then apply your toolpaths and

syncing, verify your project with simulation, and post

your code. Changes along the way are fast and easy – the

way programming should be.

Get the most out of

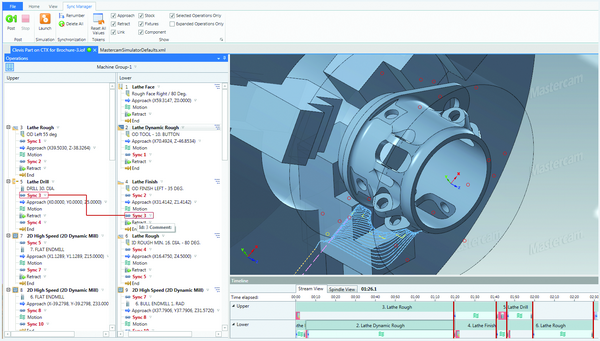

your machines with Sync Manager.

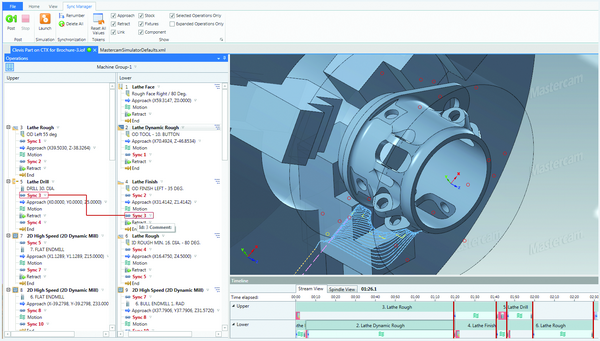

Mill-Turn’s sync

manager is a user-friendly way to optimize part cycle

times and avoid collisions before your part reaches the

machine. Mill-Turn has the option for unlimited streams

where you can drag, drop, and sync operations to your

liking. Easily navigate our Gantt-style timeline and

vertical stream interface to coordinate operations and

track cycle time estimates.

See it’s right. Know

it’s right.

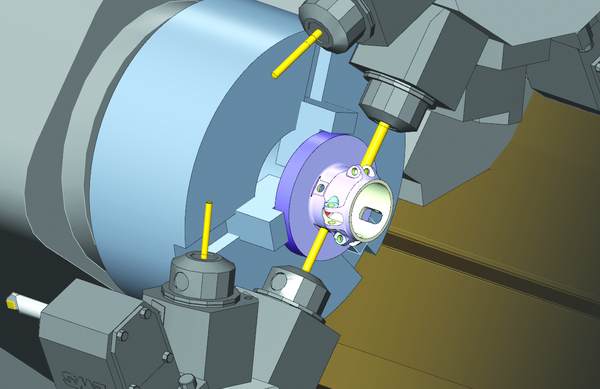

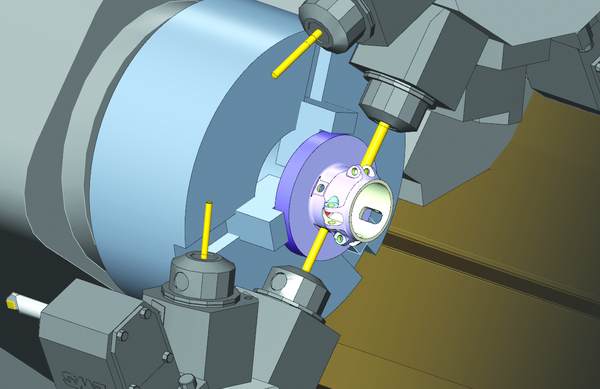

Simulation provides you with the ability

to safely and confidently run your job on your machine

environment virtually before it reaches the shop floor.

All your machine’s components and your project’s

machined stock are run on your desktop, ensuring a safe

and secure machining experience. You can identify

potential collisions, and explore ways to optimize your

processes with simulation. Also, you will be able to

view all streams and statistics of the entire machining

process, and have the capability to jump to any point in

the machining process with the click of a button.

Back to Products

CAD |

Mill |

Turn |

Wire |

Router |

Mill/Turn |

Swiss Expert |

News |

Add-ons

|