|

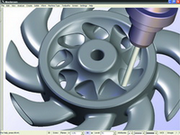

Mill

The most widely-used CAM software in the world is now

the most dynamic. Mastercam’s embedded Dynamic Motion

technology dramatically shortens production times while

extending the life of your machine and tools. Mastercam

Mill is rich in features yet still simple and intuitive

to use.

Dynamic Motion technology is truly the

next big thing in CNC machining. It’s a new way of

designing toolpaths that saves time while extending tool

and machine life.

“Mastercam’s Dynamic toolpaths

have allowed us to push our machine tools and reduce

cycle times as much as 50%.”

Jason Premo, CEO,

ADEX Machining Technologies, Greenville, SC

INTELLIGENT MACHINING SAVES TIME AND MONEY.

Dynamic Motion Technology dramatically increases machine

efficiency.

Since 2008, Mastercam has been building

Dynamic Motion into our software. That means it has been

shop-tested and proven in real-world environments.

Dynamic Motion toolpaths carve out massive amounts of

material quickly – while significantly extending the

tool life – immediately putting more money in your

pocket. Sounds unbelievable, right? But as the market

leader, we’ve had our Dynamic Motion toolpaths tested in

most every conceivable work environment around the

world. It works.

Mastercam is more widely used

than any other CAM program

For you, this means a few

very good things. First, there’s a large and

ever-growing base of potential employees already trained

and comfortable with Mastercam. More trained,

experienced, and certified Mastercam programmers makes

your workforce focused and expandable. Second, we are

shop-tested. Our software engineers are constantly

reaching out to customers to improve and streamline our

products. This makes Mastercam the easy choice for the

long haul.

Mastercam Mill, including our

cutting-edge Dynamic Motion technology, has been

shop-tested more than any CAM program in the world. You

can count on Mastercam for real-world, tested solutions.

Ultimately flexible and expandable.

Mastercam

Mill offers a broad selection of solutions for almost

every CNC milling challenge – 2D, 3D, or multiaxis.

Whether your customer base is automotive or aerospace,

medical or consumer products, energy or heavy machinery,

Mastercam Mill is ready to help you deliver.

Mastercam’s large selection of toolpaths and functions

means there’s always more than one way to get the job

done. Once you program a part, no matter how complex,

you can modify any element of the job and immediately

get updated toolpaths without starting over. You can

also build a library of your favorite machining

strategies. Choose any of your saved operations, apply

them to a part, and Mastercam helps adapt them to the

new model. Because Mastercam Mill is fully integrated

CAD/CAM, it’s fast, easy, and productive. The way

programming should be.

Mastercam’s fully

associative toolpaths let you efficiently make changes

without slowing down. Mastercam Mill’s updated Stock

Modeling, Toolpath Verification, and Simulation features

provide increased confidence on every project. The new

Tool Manager delivers a fast, efficient way to create

and organize your tooling assemblies.

Back to Products

CAD |

Mill |

Turn |

Wire |

Router |

Mill/Turn |

Swiss Expert |

News |

Add-ons

|