|

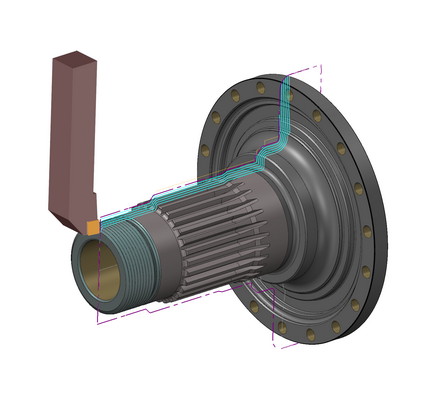

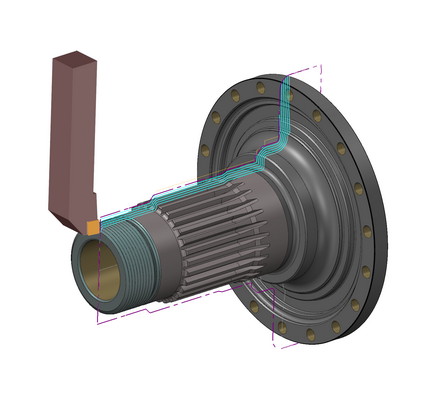

Turning

Mastercam Lathe lets you move the same part file between

milling and

turning operations with ease and

confidence.

“Harbec’s success is driven by its

focus on value. Mastercam Lathe allows us to extend its

value on to our customers with its ease of use, strong

emphasis on efficiency, and seamless transitions between

other Mastercam products. It helps us keep a turn ahead

of the competition.”

Pete Knapp, Mold Maker,

Harbec, Inc., Ontario, NY

FAST, EASY, AND

PRECISE TURNING.

Powerful, flexible tools from

the market leader.

Mastercam Lathe gives you a set of

tools that streamline your entire process. From

accepting and programming any CAD file to Dynamic

roughing and precision finishing, Mastercam Lathe gives

you a variety of techniques to turn all of your parts

exactly as you need them.

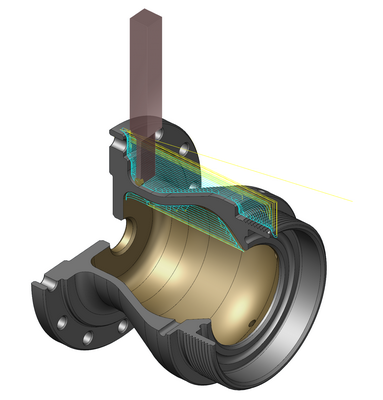

Efficient program

designed for modern manufacturing.

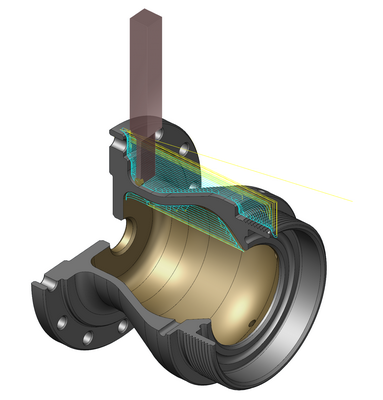

Mastercam Lathe

delivers a set of basic and advanced programming tools,

with greatly expanded options when paired with Mastercam

Mill. Easy rough, finish, thread, groove, bore, and

drill routines combine with C/Y-axis machining to cut

any job. Dependable toolpath verification gives you the

confidence to run the most complex toolpaths on your

machine, and Machine and Control Definition deliver an

easy way to help make sure your parts are done right the

first time.

Mastercam Lathe will easily cut your

turned parts and let you seamlessly move between

operations or even machines with the same part.

Key turning features.

• A set of “Quick

Toolpaths” that let you program in a few clicks.

•

Intelligent ID and OD roughing, featuring both Dynamic

and variable cutting.

• Fast facing including

roughing and finishing.

• Grooving with multiple

depth cuts including peck motion and also full-radius

plunge turning.

• Complete threading with multiple

starts, diameter calculation, and thread tables.

•

Automatic gouge checking watches the front and back of

the tool.

• Chuck, part, steady rest, and tailstock

detection.

• Open and directly machine a solid model.

• Quick-turned profile generation for uniform and

non-uniform parts.

• Full milling support available

for machines with live tooling for C and Y axes.

Back to Products

CAD |

Mill |

Turn |

Wire |

Router |

Mill/Turn |

Swiss Expert |

News |

Add-ons

|