|

Moldplus

Moldplus, a Mastercam Third Party Partner, offers

powerful advanced design tools for the Mastercam user.

Originally designed for the mold industry, the software

solution now offers even more tools for various

industries ranging from the aerospace to the medical

industry, that use CNC machines or robots for

manufacturing purposes. Powerful trimming and untrimming

surface tools, along with surface patching tools,

continue to be a great help for Mastercam users. The

solution is offered in different levels and packages to

cater to the needs of the client.

Moldplus V10.7

The new version of Moldplus offers several new features

to the 5-axis toolkit and various internal enhancements

to the overall software solution. Below are some of the

highlights of the new version:

-

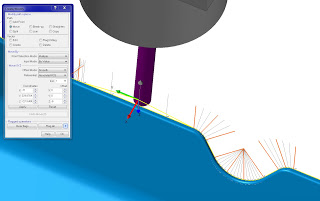

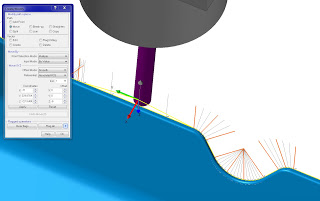

Create Mastercam Curve 5axis toolpaths with 1-click—Once

the geometries for the curves and vectors are

created using the automatic function or the manual

edge selection method, the geometry can be directly

passed to the Mastercam curve 5-axis parameters and

have the toolpath created.

-

Create curves on edges and splines—Create curves

and vectors by clicking on edges. Also, output the

curves as parametric splines to allow for better

machining results.

-

Welding geometry—Quickly identify and create

welding geometry (curves and vectors based on the

intersection of edges) for the robotic welding

industry where creation of such geometry is a

tedious and painstaking task.

-

Isolate inner and outer shell face enhancements—The

selector for isolating inner and outer shell offers

a slide bar to select faces on complex models more

easily. Fillet faces (concave or convex) alone can

be isolated and stored on separate layers.

-

STL Utilities—The splitting interface has been

improved with new tools for dynamic preview of

slicing the STL bodies, ability to preview and

create closed bodies, easier management of split

bodies, and direct saving of the bodies as Mastercam

entities. The STL create edge function also allows

for previewing the edges that will be created and

storing the body and edges directly as Mastercam

entities.

Today’s competitive environment and globalization

requires that mold makers manufacture molds cheaper,

faster and better than ever before. Moldplus will allow

you to meet these requirements while remaining

competitive and profitable.

Moldplus is a family of powerful software tools

specifically desgined for the advanced needs of

toolmakers. For many years builders of complex tools

have been using market-leading Moldplus products to help

design and manufacture their molds, dies, models, and

fixtures in the shortest possible timeframe with high

quality and maximum profits.

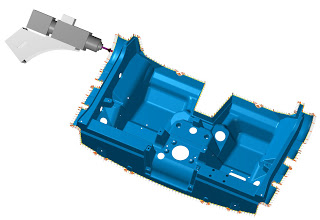

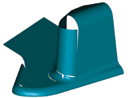

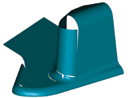

Moldplus enables you to determine draft angles, split

core and cavity surfaces, create parting lines, design

complex run-ff surfaces and even manufacture EDM

electrodes. With Moldplus, precious machine time

is never wated because you can be sure that the tool

will be correct, functional, and of the highest quality

before any machine tool is set-up or a single chip is

made.

Model-makers, mold-makers, pattern-making, aerospace

industry, and anyone involved in surface or solid

modeling, Moldplus is the solution.

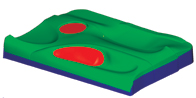

Before |

Before |

After |

After |

|

1-click Draft Surface Creation. |

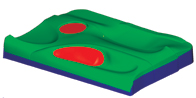

Fix bad surface models. |

Moldplus Standard consists

of surface trimming and extension tools, mold design

tools such as Draft Angle Analysis, Core and Cavity

separation and parting surface creation.

Moldplus Professional includes

tools for untrimming surfaces, healing/fixing surfaces

and tools to make Electrodes and surface extensions for

vacuum forming tools. This package includes all of the

features available in the Moldplus Standard package.

Moldplus Super Trim consists

of all the trimming and untrimming features of Moldplus.

These tools are handy to heal/fix bad surfaces or

manipulate surface trim boundaries and patch complex

holes.

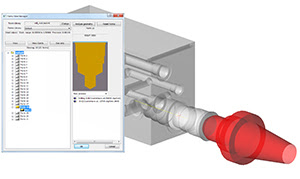

ProDrill

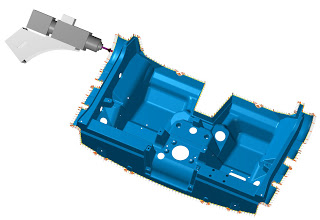

Moldplus also offers a product called ProDrill. This

software lets you perform advanced feature-based

drilling in Mastercam. ProDrill V4 lets you drill what

you want, when you want, and how you want it from

surface or solid models. The latest version, ProDrill

V4, is attracting attention because it gives users the

flexibility to choose complete automation or full manual

control when programming drilling tasks. This version is

also attracting the hydraulic manifold manufacturing

market, where programming parts using form tools is very

time-consuming. ProDrill users who use Mastercam for

both simple and complex drilling depend on it for their

just-in-time manufacturing needs.

Here is a quick look at what is offered in the latest

version, ProDrill V4 MR1 SP2:

-

Sort points graphically by lines –

This new function lets sort points by dynamically

sketching lines to indicate the direction for the

drilling points. Tolerance control is offered to

select points that are close to a sketched line.

-

Form definition enhancements –

Library forms that are stored and processed are only

stored for cylinders that can be machined from an

indicated direction. Forms that need to be split for

machining from both sides need to be manually or

automatically split before applying drilling

processes.

-

Closest form identifier –

Identify differences in minor diameter length and

chamfer diameter AND apply existing library forms

that match these parameters within a given

tolerance.

-

Define entry and exit parameters for Contour

operations –

The Contour settings dialog now offers options to

define entry and exit controls for the library

forms.

Moldplus is continuing to improve their interface and

working on offering several new tools for the emerging

market needs.

www.moldplus.com

Home | Products | News | Events | Support | About |

Links

|